Why Are Perforations Used in Shrink Sleeve Packaging?

There are few things more frustrating for a consumer than being unable to easily open a package as intended, and they must pick up a knife or scissors to get at the product inside. That is of no service to a brand or to a company’s hard-gained customer loyalty, but rather the opposite. People get aggravated and may not choose to buy that product again. In many cases, poorly perforated safety seals are the culprit.

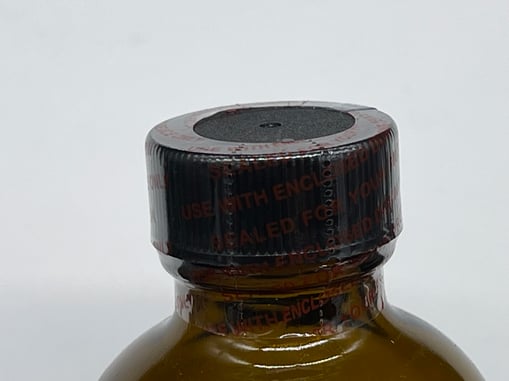

Perforations on shrink sleeves perform a number of functions. On neck bands, perforations make it difficult to open or tamper with a product without it being obvious to the consumer. They allow the top portion (tamper evident band) of a full body label to be removed from around the cap, leaving the primary graphics remaining on the body of the package. Perforations can also be used to make it easy for the customer to remove the sleeve for recycling purposes.

Three Primary Perforation Types: Full Vertical, Horizontal and Partial Vertical, and Venting

Full Vertical Perforations

Full vertical perforations are commonly used to easily remove a tamper evident neck band from around the closure and shoulder of a jar, bottle or tub. This perforation is visibly damaged when the package is opened and is therefore “tamper evident”. A full vertical perforation can also help remove a full body shrink sleeve from a product for ease of recyclability.

Horizontal and Partial Vertical Perforations

Horizontal perforations, often including partial vertical perforations, are used when a full height shrink sleeve label extends up over the closure to provide tamper evidence. When opening, the consumer removes the portion of the sleeve above the horizontal perforation, exposing the cap or closure which can then be opened. This leaves the label on the body of the package intact.

Venting Perforations

Venting holes or perforations are not part of tamper evidence, but are added in the shrink sleeving process to allow air to vent from under a sleeve while shrinking over a concave indentation in a package. This prevents air from being entrapped, allowing the sleeve to conform to the sidewalls of the indented areas. One or two holes per side of the label, spaced apart, are typically enough to let the trapped air escape.

What Is Needed to Make a Neck Band Tamper Evident?

The neck band must underlap and grip an indented area (neck ring) below the cap so that this area is visibly damaged when the band is removed and the cap is raised to open. If not, the cap could be removed and replaced without visible damage, and the band is therefore not “tamper evident.”

Full Vertical Perforations

In order to provide visual evidence of opening, It is important that the vertical perforation has the correct strength. It must break and separate when the cap is removed to indicate opening or tampering. Yet, it cannot be so weak that it breaks prematurely, which can cause waste or product rejection at the store by the consumer.

Horizontal and Partial Vertical Perforations

Once again, with horizontal and partial vertical perforations, strength (tensile strength of the perforated web of labels) is critical. The perforated web, ready to be applied to the container, cannot be so weakened that it breaks when being driven through the sleeve applicating machine. But it must be weak enough so that it breaks correctly under normal circumstances after shrinking.

In addition, during shrinking in the heat tunnel, the material is pulled by the shrink forces of the film. If the perforation is too weak it will break in the shrink tunnel. These perforations must lay against the side of the container rather than in areas where air is behind them, such as where the sleeve bridges between curves on the containers. If not positioned properly, perforations with air behind them will “blow out” and separate while being shrunk, damaging the label, which is then not saleable.

PDC manufactures a broad range of shrink sleeve labeling and neck banding machinery for the application of heat shrinkable tamper-evident seals. We have years of expertise in helping customers choose the proper perforation method for a variety of product and packaging types. Our Shrink Lab is available to test your product and determine the correct perforation to ensure it functions as intended, protecting your customers, your brand and your reputation.